Scroll through some Reddit threads or hobbyist Facebook groups and you’ll find it: the relentless discussions over 3D printing and food safety. According to internet folklore, the mere touch of a printed object on cookie dough could unleash a storm of bacteria, lead and microplastics into your body. But is this panic really justified?

Let’s take a breath and unpack the real science, regulations and common sense behind the question: Is 3D printing food safe?

Food Safe 3D Print vs Food Contact Safe 3D Print — Do You Know the Difference?

Before we go deeper into today’s topic, let’s differ “food safe” from “food contact safe”. The difference between a food safe 3D print and a food contact safe 3D print lies primarily in the scope of safety standards and intended usage:

- Food safe 3D print means that the printed object is made from materials and processes that do not pose any health hazards if ingested or if in direct contact with food; the entire product is considered safe from harmful substances. This includes using non-toxic filaments, avoiding harmful additives, and ensuring no contaminants or residues from printing processes remain. It implies a higher overall level of material safety suitable for long-term or direct contact with food.

- Food contact safe 3D print specifically refers to objects that are safe to have direct contact with food under regulated standards but may not guarantee the entire object is inherently food safe if, for example, it degrades, leaches, or is used in unintended ways. This classification often aligns with regulatory approvals (such as FDA compliance) for short-term or specific types of food contact, focusing on preventing contamination through migration of harmful substances during contact.

Ensuring either requires using certified food grade filaments, proper printing hygiene and sometimes post-processing to avoid rough surfaces or contaminants that may harbor bacteria or leach chemicals. And I would like to kick it off with the “bacteria between the 3D print layers” argument.

Surface Texture = Bacterial Risk?

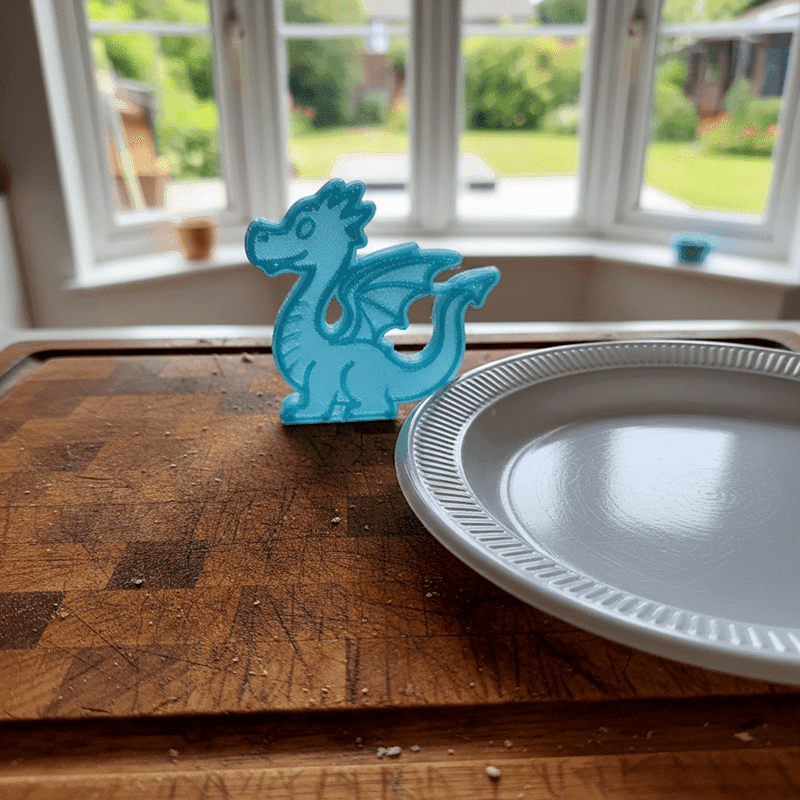

One of the biggest fears surrounding 3D printed food tools is bacterial contamination from layer lines. And it’s true that bacteria like to cling to rough surfaces. But if that makes 3D prints dangerous — so are your cutting boards.

Wooden cutting boards end up full of knife grooves. Plastic plates get scratched over time. Even metal utensils develop micro-abrasions with regular use. These are all places bacteria can hide. The science backs this up. According to studies, surface roughness — no matter the material — increases bacterial adhesion. But here’s the key: cleaning practices matter far more than surface texture alone.

That said, it’s fair to note that complex or fragile 3D printed objects may be harder to clean thoroughly, especially if layer adhesion is poor or the geometry has deep gaps. Still, if you can clean a cutting board, you can clean a PLA / PETG 3D print — if it’s printed well and designed with food safety in mind.

PLA / PETG — Always a Food Safe Filament?

There’s a lot of confusion about materials like PLA and PETG. Are they food safe or not?

In their pure form — yes, they are.

- PLA is listed as Generally Recognized As Safe (GRAS) by the FDA.

- PETG even goes further — it’s used in many commercial food containers and bottles.

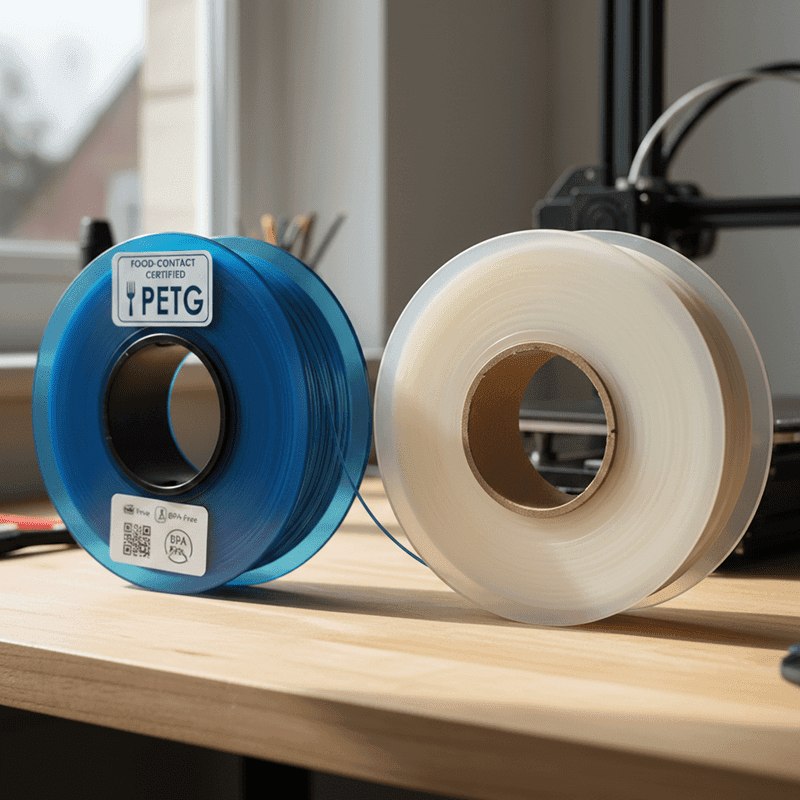

But here’s the catch that many people overlook: not all filaments are pure. Consumer filaments often contain colorants, softeners and other additives — none of which are guaranteed to be food-contact safe.

That’s why checking the filament manufacturer’s documentation is crucial. Some brands sell certified food-contact filament. Most — don’t.

And food safety doesn’t stop at the spool. Think about your printer:

- Is your nozzle clean?

- Have you printed abrasive or industrial materials with it?

- Is your print bed clean and used only for food safe objects?

Even the safest material can be compromised by a dirty setup.

Lead Fears, Brass Nozzles and one Outdated Myth

Another common fear is lead contamination from brass nozzles. The concern is rooted in truth — old brass alloys sometimes did contain lead. But modern, reputable nozzle manufacturers now follow strict regulations like RoHS (Restriction of Hazardous Substances), which limits or eliminates lead.

And even if a trace of lead did exist, the likelihood of it transferring through extrusion and ending up on a printed surface is virtually nonexistent. Brass nozzles don’t touch your food — they touch filament, which is melted and cooled. No real life studies or evidence show harmful amounts of lead making that journey.

Still worried? Swap your brass nozzle for stainless steel. Problem solved.

The Microplastics Drama

Perhaps the most emotionally charged fear is about microplastics. We hear about them in the news, in oceans, in fish — and now, apparently, in every 3D print too.

But here’s the scientific reality:

- Tap water contains microplastics.

- Bottled water contains even more.

- Household dust is loaded with them.

- Most plastic packaging sheds particles over time.

A simple PLA cookie cutter or 3D printed drinking mug isn’t introducing some exotic new threat to your life. If anything, it’s shedding far less than store-bought items made from cheaper, fast-degrading plastic.

Still, there are ways to minimize any risk:

- Sand or smooth the surface after printing

- Design prints with fewer sharp ridges, fragile edges or hard to reach (for cleaning) areas

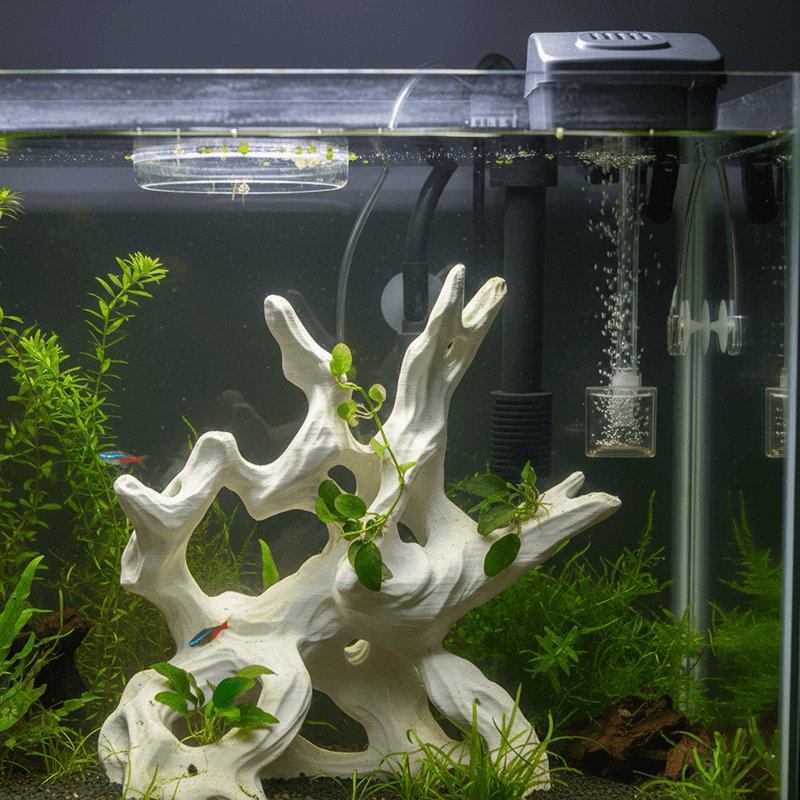

And let’s not forget: many aquarium decorations and functional parts are already plastic. If a 3D printed cave made of PETG were truly dangerous to aquatic life, every tank would be a toxic wasteland. They’re not. In my opinion — resin is much more of a concern in tanks, but it’s used even more videly.

Cleaning: Can You Really Sanitize a 3D Printed Object?

Here’s where things get practical.

A 2023 study tested how well standard kitchen cleaning methods work on PLA and PETG prints. The results were refreshingly simple:

- Soap and warm water removed most contamination

- Mild disinfectants cleared biofilms

- Well-designed shapes (no hidden crevices) were easiest to clean

However, not all prints are created equal. PLA can deform in hot water above 60°C, so the dishwasher is out. Low infill designs or sloppy layer adhesion may also trap grime more easily. Still, this isn’t a deal-breaker. Most people already hand wash delicate plastic tools. An I do believe, that what you plan to 3D print, won’t be a surgical instrument.

For more insights on safe Aquarium & 3D print cleaning methods check out my topic here.

Final Verdict: is 3D Printing Food Safe?

FDM 3D printing isn’t inherently dangerous. It’s not a biohazard. And it’s definitely not some secret microplastic bomb waiting to explode in your salad bowl. But like any tool, it requires smart use:

- Know your materials

- Clean your gear

- Post-process your prints when needed

- Design for hygiene

The internet is full of outdated fears and half-truths. But modern research shows us that with the right approach, PLA and PETG can be used safely in food-contact applications — especially when you’re printing for yourself.

So no, you don’t need to fear your prints. Just don’t dip it in boiling water or print it with mystery filament off AliExpress (Ali – no offense 😉). Stay curious. Stay informed. And most importantly — stay printing.

Liked the topic? Make sure to check out also these insights:

- Is 3D Printing Food Safe? Here’s the Real Truth

- 3D Printed Reptile Hides Exposed: Crucial for Welfare or Just Terrarium Decor Hype?

- 3D Print Bed Adhesion — What Works Best To Avoid Failed 3D Print?

- Are Aquarium Caves Really Critical for Fish and Shrimp Health? Does 3D Print Decor make a Difference for your Aquatic Pets?

- Why Aquarium Plant Holders Are Changing the Game for Tree Lovers