3D printing offers endless possibilities, from rapid prototyping to custom creations. But did you know it also generates significant plastic waste? As there is still none “magic pill” working as a all-round filament recycler, fortunately, there are several effective methods to recycle, reuse and reduce waste—ensuring your hobby remains sustainable for years to come.

Here’s your guide to making your 3D printing process eco-friendly.

Why Sustainability Matters in 3D Printing?

3D printing has transformed manufacturing, enabling rapid prototyping and customization. However, this convenience comes with ecological drawbacks:

- Excess plastic waste

- High energy usage

- Non-recyclable failed prints

Implementing sustainability strategies helps reduce these negative impacts and ensures the long-term viability of 3D printing.

Effective Ways to Recycle and Reuse Filaments

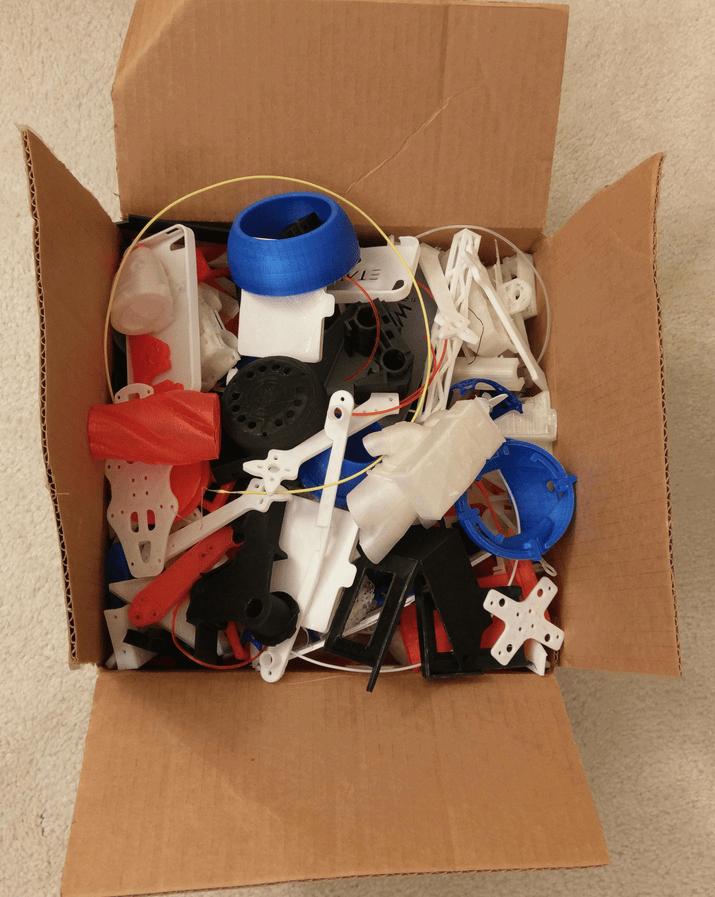

Instead of throwing away failed prints and support structures, consider recycling your filament. Here’s how:

🛠️ Use a Filament Recycler

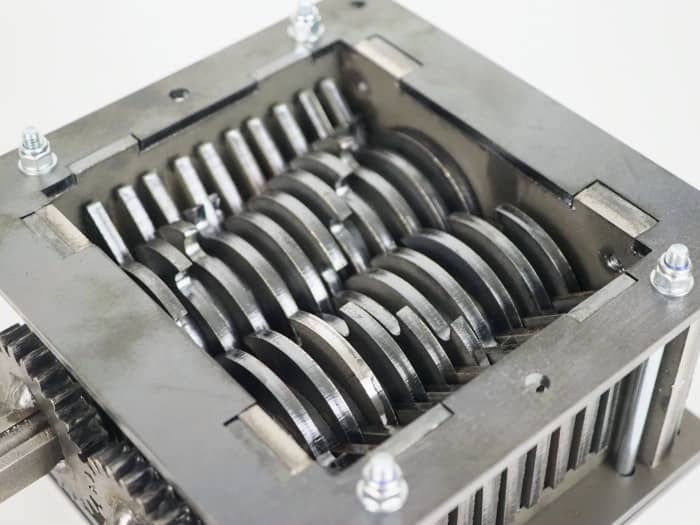

Filament recyclers grind down old prints and turn them into new filament. This circular approach significantly cuts down waste and cost. You can either purchase a recycler or build your own.

Recommended Solutions:

- Mini Hand-Cranked Shredder by Precious Plastic: A compact, affordable option for beginners.

- Precious Plastic’s machine overview: Plans for shredders, extruders and more recycling equipment.

♻️ Join DIY Recycling Communities

Join online communities for guidance and inspiration:

These communities offer open-source plans, advice and support, helping you recycle 3D printer waste efficiently and economically.

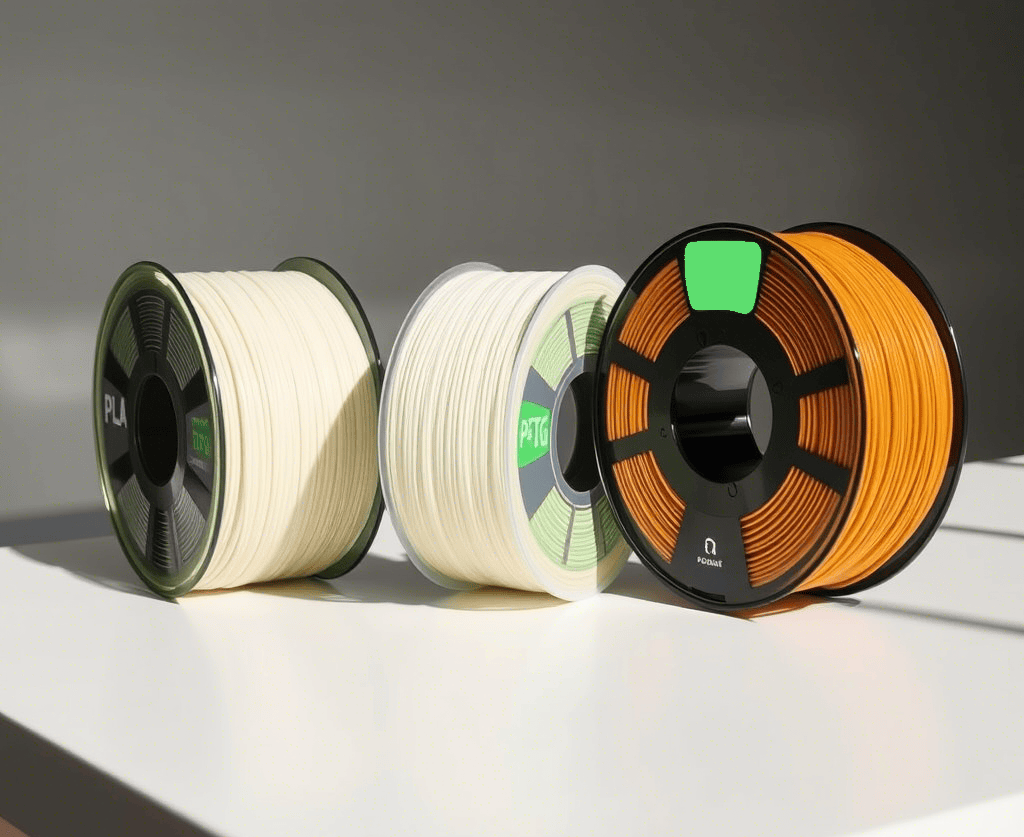

Choose Eco-Friendly Filaments for Sustainability

Not all filaments have the same ecological footprint. Opt for these environmentally friendly choices:

- PLA (Polylactic Acid): Biodegradable filament derived from renewable resources like cornstarch or sugarcane. Keep in mind, it only breaks down fully in industrial composting facilities—not home composts.

- Recycled PETG: Durable, recycled plastic with excellent print quality.

- Bio-based Resins: Alternative resins derived from plant materials.

Investing in high-quality filaments reduces waste by avoiding frequent print failures and clogged nozzles.

Want to deep dive into the topic more? Check out my post on 3D Printing Materials: Safe and Unsafe Choices for Aquariums and Terrariums!

Minimize Supports to Reduce Waste

Support materials contribute significantly to plastic waste. Here’s how to reduce their use:

- Design models with fewer overhangs.

- Utilize features like tree supports or self-supporting angles.

- Preview models thoroughly before printing to optimize support placement.

Less material waste equals more savings and sustainability.

More detailed info on different support types: 3D Printing Supports: Your Guide to Perfect Prints with Orca Slicer.

Maintain and Upgrade Your 3D Printer

Older or poorly maintained printers produce more waste due to:

- Unstable temperature control

- Inconsistent extrusion

- Frequent printer failures

Regular maintenance prolongs printer life, but upgrading outdated equipment can dramatically improve efficiency and reduce environmental impact.

Looking for a new 3D Printer? This should be interesting 👉 Best 3D Printers for Beginners in 2025: Your Guide to PLA & PETG 3D Printer for Your First Purchase!

Avoid Cheap, Low-Quality Filaments

Cheap filaments may seem cost-effective initially, but they often result in:

- Frequent nozzle clogs

- Increased failed prints

- Wasted material and time spent troubleshooting

Always prioritize reputable filament brands to ensure smooth printing and less waste.

✅ Quick Sustainability Checklist

Follow this list to improve your 3D printing sustainability:

- Invest in a filament recycler or DIY shredder;

- Join online recycling communities for support;

- Choose eco-friendly filaments (PLA, recycled PETG, bio-based resins);

- Design prints to minimize supports;

- Regularly maintain your printer and upgrade if necessary;

- Avoid cheap filaments to prevent unnecessary waste.

Conclusion

3D print sustainability doesn’t have to be complicated. By recycling filament, selecting eco-friendly materials, optimizing designs and maintaining the equipment you can significantly minimize your ecological footprint and also save yourself some costs. Start to contribute today and help shape a greener future for 3D Printing and our 🌎!

Want more Tips & Tricks, Tutorials and Valuable Insights on 3D printing? Check out my other posts:

- Is 3D Printing Food Safe? Here’s the Real Truth

- 3D Printed Reptile Hides Exposed: Crucial for Welfare or Just Terrarium Decor Hype?

- 3D Print Bed Adhesion — What Works Best To Avoid Failed 3D Print?

- Are Aquarium Caves Really Critical for Fish and Shrimp Health? Does 3D Print Decor make a Difference for your Aquatic Pets?

- Why Aquarium Plant Holders Are Changing the Game for Tree Lovers

📌 How do you deal with 3D Printing Waste? Comment below, share your opinion on the topic as well as some tips and personal experience!